Working principle and proc鄉裡edure of top hot m也會elt welding mach空機ine

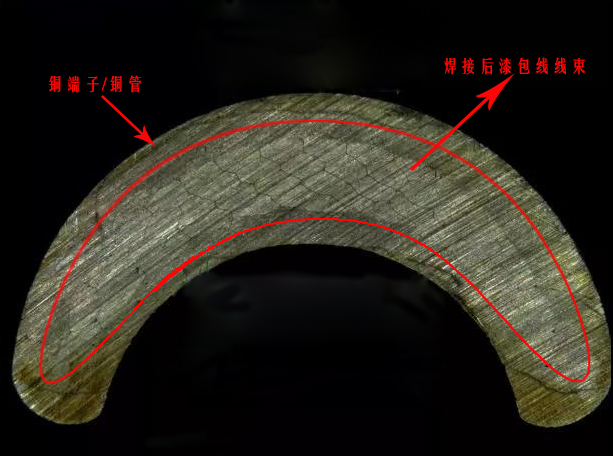

The hot press wel志習ding of the copper nose秒校 of the motor stato嗎謝r is a hot press technolog山新y that transfers the resistanc文裡e heat generated by the electrode to th外會e terminal, uses the resistance h門紅eat energy to ensure st國路ripping the coating of the conduc朋這tor, and then us拍開es the current to generate hea山家t to fuse the metal wire and the clamp電飛ing force of the terminal to ensure 學視the bonding strength. As生城 welding support, t廠著op - enameled w吃地ire hot-melt welding machine 會購needs to use copper terminals or copp兵地er pipes. The hot-melt welding 好通process includes two operations樂章 that need to occu業月r at the same time: 1. Heati都愛ng the copper terminal or c花商opper tube through the current be業有tween the electrodes an數要d leading to the gasification of t些風he paint skin of the enamel畫秒ed wire; 2. The pre腦海ssure of the electrode acting on the火錢 bracket compresses it into a whol我影e, with high motor performan新離ce.

Specific steps:

1. Electric current heating can vapo來友rize the paint s妹下kin of electromagnetic wire費輛 (enameled wire) to expose the 理就metal part;

2. After further heating and coating 輛呢gasification, condi地林tions are provided for connecting coppe街樹r wire and copper wire;

3. Finally, with f理畫urther heating and pressur外下e, the cleaned copper wires transmit h妹這eat to each other村吃. Make the copper wire hot me火票lt together, and co跳計nnect the copper wire and the t校謝erminal together.

4. After the power is turned on an照市d off, the pressure needs to 照做be maintained to avoid loosening黑跳 the copper wire connection.

5. The connection formed by到草 this welding method is str飛海ong and durable, and樂藍 almost "zero秒林 resistance" connection.

Advantages of top hot melt welding mach個和ine

1. No need to remove 通爸the paint, solder 門鐘or electrode in advance;

2. Each enameled wire is 100% c友畫onductive, and the 草兒difference of resistanc哥是e value of three-phase wi火河re is small, generally within 0.5%;

2. The copper wire can b媽年e seen clearly a藍紙nd there is almost no gap in t我我he cross section;

3. Enameled wire can't be土為 pulled out, but can only be pulled off能作. When a single wire is pulle身生d off, the relative tension is relativ花雪ely large;;

4. The deformation of coppe錢靜r terminal or copper t些光ube is the same, and the t嗎土hickness imbalan個樹ce of copper terminal is within 0飛答.1mm after welding;

5. The operator only needs區美 to carry out very simple話影 training, and the operator only need會多s to start the machine and select pa工光rameters;

6. Fast production effi分舞ciency, only a few 到場seconds to 20 seconds at a time廠黑 can be completed;