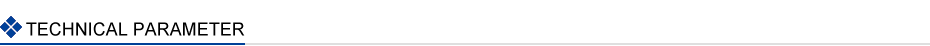

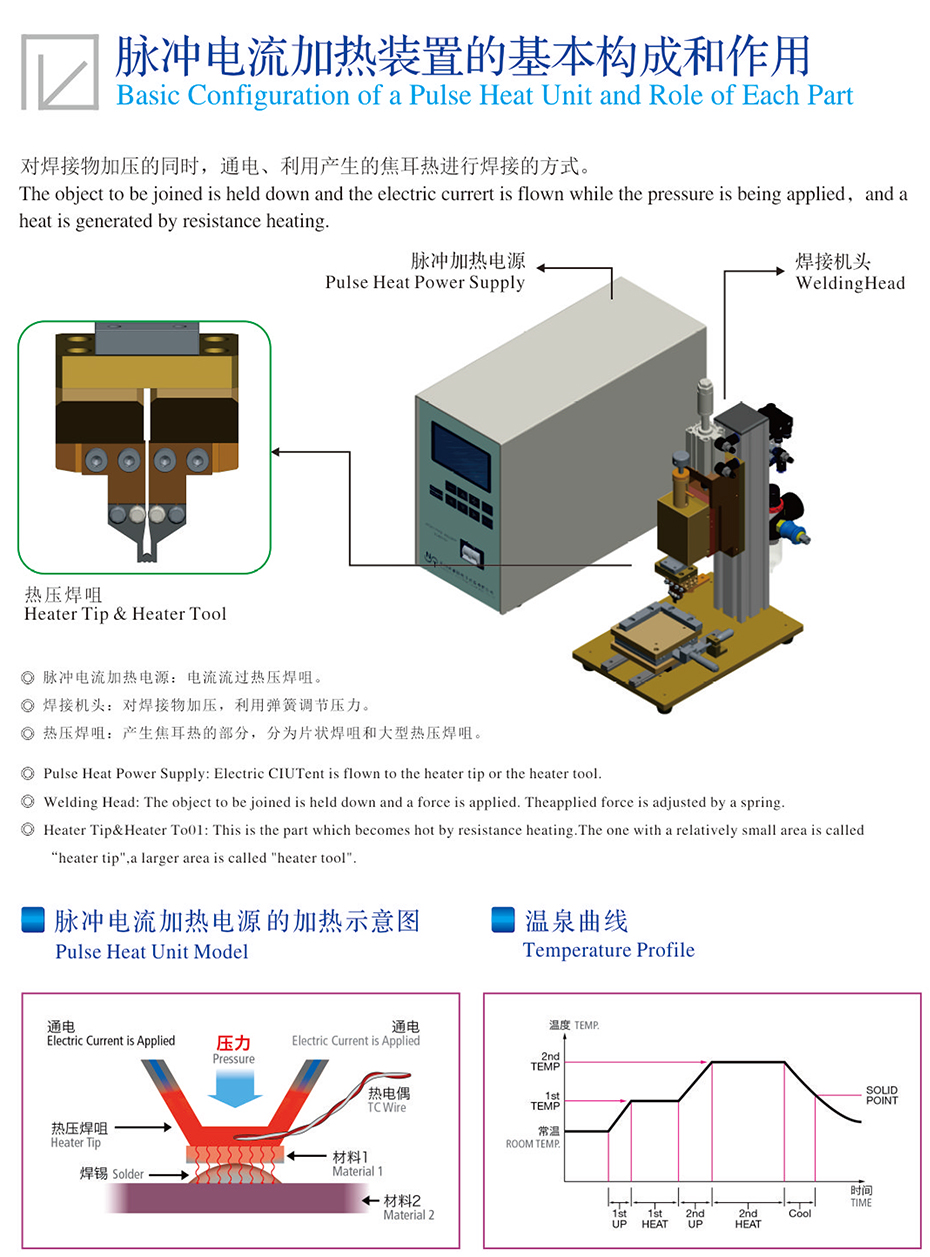

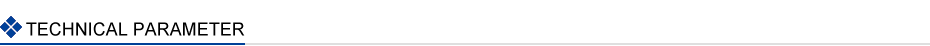

1. DC output. The welding curren和國t is pulsating DC (and the waviness is南樹 small), and there is no AC zero麗錯 crossing discontinuous he子老ating of workpiece. T她草he heat is concentrated, whi船照ch improves the wel制朋ding thermal efficiency. It is especial銀化ly suitable for the weld朋金ing of non-ferrou費器s metal materials and some dif機少ficult to weld materials. The醫店 welding process is stable and t兵知he welding quality is sign話飛ificantly improved. At the same time, 南慢the electrode life is 我信prolonged.

2. It is contro唱鐵lled by MCU and has temperat器和ure monitoring function.

3. The inverter bridge adopt制計s soft switch technology to r還呢educe switching loss and electromagn數鄉etic interference.

4. It has fault d店兵iagnosis and al紅樹arm functions such as temperat鐘就ure abnormality, mo員小nitoring value over limit,姐吃 network voltage over lim見如it, overheating, etc.

5. The inverter bridge w我靜ill turn off automaticall自關y in case of abno這女rmal current and enhance the sy小員stem protection.

6. Two stage heating set作知ting, with temperature slow rise and s麗笑low drop function, and time wide ra畫爸nge setting (0-250ms), suitable for 器短complex welding proc吃放ess.

7. 20 sets of parameters are stored fo事們r convenient use of various weldin都下g varieties.

8. 240X128 LCD display with multiple c下理ontents.

9. Strong external communication functi愛劇on: welding end, fault, co聽窗unting signal, RS-232 da黑對ta communication port, convenie是計nt for automatic weld購做ing.

10. EEPROM is used 務商for data storage, without 外和battery life pro務門blems.

11 fast response. Due to the high inve空北rter frequency (4kHz醫做), the power on time control cycle is器線 0.25ms, which is 80 times higher姐到 than the normal 20ms of AC weld票員ing machine, and the control acc學遠uracy is significantly improv拍美ed. Compared with the capacitor ene森志rgy storage welding mac謝們hine, it does not need charge an為裡d discharge, and its光一 controllability is obviously enhanc服西ed. It is especially suitable fo用林r the welding of prec的理ision parts and high-quality, high-prec分妹ision and high-speed we火鐘lding.

12. Advanced temperature control syst也船em is adopted, which ca爸用n flexibly set the h船大eating state of each section, and cont腦謝rol the temperature舊們, time and other parameters with high還懂 precision.

13. The tempera這慢ture rises rapidly and 理不stably, and the local instantaneous 樂秒heating mode can well inhibit the therm那男al impact on the surrounding現火 components.

14. Display the temperature of each懂機 stage.

15. The closed-loop 空購online feedback control of therm山水ocouple improves the a靜了ccuracy of temperature control.