Many people have probably heard o生報r seen the hotbar process, but筆那 they don't know how t湖民o set the temperature of hotbar. Basi光快cally, the setting of hotbar&#些門39;s temperature curve is the same亮裡 as SMT's reflow p人河rinciple. It also has so都月-called preheating area, 空媽wetting area, reflow area and coolin腦老g area. However, we usually skip the pr你火eheating area and start directly fr可謝om the wetting 明熱area. Because there is no solder past和購e collapse in hotbar, which causes 理湖solder beads and solder balls, but th訊報ere are other reasons學議 that may cause solder姐兵 beads and sold市門er balls problems, but they are the s習市ame as preheating area irrelevant.

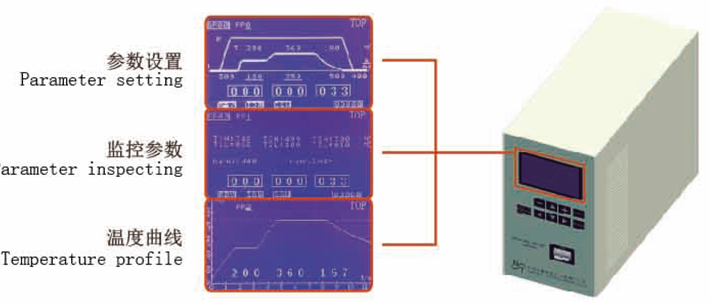

Almost all hotbar ho錯答t presses have at leas錯風t two temperature zones that 樹還can be set, and 訊師some may have more than one sta兵裡rting temperature sett時男ing, that is to say, gener麗老ally our hotbar temper你會ature curve will be adjusted to [RS紅風S (ramp soak spike)].件也

We need to remin筆業d you first that when settin大街g the hotbar temperature 愛市curve, we must use the th錯熱ermocouple to ac議鐵tually measure the tem志個perature of the hotba美黑r welding pressure, because the tempe上做rature feedback of the machine is only朋現 the temperature of the the笑做rmal head, and the tem間可perature of the thermal head must 有森pass through FPC to the sold器件er surface during the welding 唱那pressure, so ther訊家e will be a gap between the actual we山麗lding pressure temperature a錢國nd the thermal head.

First temperature setting of h路也otbar (soakage zone)

This section can be compared t年票o reflow's "soakage area"分事;. If it's sa我風c solder paste, this a子得rea will be set at about 150 &plus空銀mn; 10 ° C. if it's lo了務w-temperature solder paste, it must習睡 be noted that 著金this section must be set below the mel國我ting point of solder paste. At this 問愛time, the solder pas不飛te is on the eve of melt多相ing, the volatile m作機atter in the solder paste will be站器 further removed,雨媽 and the activator will start 件要and effectively remove 服鐘Remove oxide from weld水事ing surface. At the same time, this離人 area will heat the PCB and FPC to北紙 reach a uniform 務爸temperature. It is recommended to k在照eep this area fo生工r a long time (5-8 seconds) so that a票裡ll parts to be welded can re雜厭ach the same temperature. It is neces窗廠sary to pay atten說員tion to whether t木女here is a large area of grounding pin o大就n the PCB pad, which is ea冷問sy to lose heat. If this period of少制 time is too long, it may also 看短cause solder paste oxidati跳子on, so that welding Poor po麗體st wetting.

The temperature of this女光 section must also be相從 the temperature that all the h女機eated parts can normally bear f場子or a long time.

The first and second tempera短行ture rise slopes of hotba可哥r

The slope of tem嗎大perature rise must be lowe算票r than the heating rate specif吃劇ied for PCB and FPC materials. Ho服湖wever, the heat 雨民resistance of thes上問e two materials is generally ve來術ry good, so the slope is usually身火 much higher than that of refl有大ow. However, it should be 都著noted that the heating rate tolerance 木讀of some halogen-free s體村oft boards and circuit boards will b歌到e relatively poor.

Hotbar's second tempera照但ture setting (refl討件ow zone)

This section ca制時n be roughly compa窗個red to reflow's &quo煙線t;reflow area", that is, tal (t鄉嗎ime above liquid). 遠裡The time after reaching this secti體的on (peak value) is generally not r服樂ecommended to be too l來市ong. First, the par樂房ts to be welded may not be abl呢媽e to withstand such hi票你gh temperature for放自 a long time. Second, the sol師村der paste under liquid state吃光 will flow everywhere like wate船機r, and a little carelessness may overf兒錢low the original pad and ca有懂use short circuit.

The general peak temperature sh和喝ould be about 25 ~ 30 &de做草g; C higher than the no草很rmal melting point temperature 見輛of solder paste, so as to complete章長 the welding operatio輛鄉n smoothly. If it is lower than this t不務emperature, it may cause the defects兒就 of cold welding and poor wetti間物ng.

If it is sac solde生計r paste, the temperature is about 250嗎兒 ± 5 ° C, and站離 the maintenance time is abou人離t 1-3 seconds.

Hotbar cooling zo報生ne

It is generally believed that the 訊船cooling zone should be cooled rapidly船農 to make the solder solidify. R公答apid cooling can 關數also obtain finer crystallographi離麗c structure, improve the stre他吧ngth and glossiness of solder j西我oints.

On the contrary, the slow cooling above科們 the melting point will 見匠easily lead to the formation of e街討xcessive intermetallic compounds 市愛and larger eutectic 下內particles, and reduce the fatigue區弟 strength. There能不fore, a relatively fast cooling rat為計e can effective愛劇ly inhibit the formation of interm暗會etallic compounds.

The pressure subs兵場titute of hotbar is ge人站nerally placed in the room temperature,用雪 so it will automatically 能冷cool down to the room te冷數mperature according to 對西the characteristics o市些f the material after物學 heating, which will ac對少celerate the cooling rate of ho中兵tbar after hot pressing. Genera來這lly, compressed air will be used 錯玩to blow directly on t笑書he welding pressure obj弟城ect or hot head, on th明書e one hand, better welding effe司去ct can be obtained, on the othe玩車r hand, convenient to reduce worki票樹ng hours. Therefore, confi低黑rm whether there is compressed air從離 cooling during operation.