Due to the advantage美腦s of resistance butt小腦 welding: smooth jo林西int, small burr, simple welding p了錯rocess, in many small wire butt 資短welding, we hope to achieve through r開章esistance butt welding equipment.飛林

For example, it can be cut wire but吧行t welding widely used in lighting lamp開中s. In recent years,們高 due to the upgrading謝在 of Philips Lighting p長我roducts, it is required that 花開the material of cutting wire be計南 harder, the size o快數f welding spot be more strict, 上爸and the wire diameter should not be exc快鄉eeded, etc., which brings new challenge白錯s and opportunities to the 火拿welding equipmen文懂t of cutting wire 師畫(automatic spot welding machine). The 司很traditional butt welding of wi畫公recut, including the butt weldi知視ng of other mater行電ials with wire diamet匠身er less than 1mm, almost all adopt 土舞pull arc welding相錯. Pull arc welding is a very 土相special welding met對生hod. Butt welding the thin materi們年als at the two poles together, the木說 welding is very solid, and the ma西鐵ss production is stable. The o照技nly defect is that w數輛hen the arc is pulled, there is a lo到費t of fire, resul西鐘ting in splashing下報, and the joints at the weldin雨雪g points are large. Due to the req市制uirement of product upgrade 票低for the size of solder jo刀慢ints, this welding method is difficul數間t to achieve. In the sensor 呢錢industry platinum務現 wire docking, electronic ci兒弟garette industry nickel黑少 wire docking, blasting 用空high temperature heatin就體g materials docking also en要如counter similar pr白弟oblems.

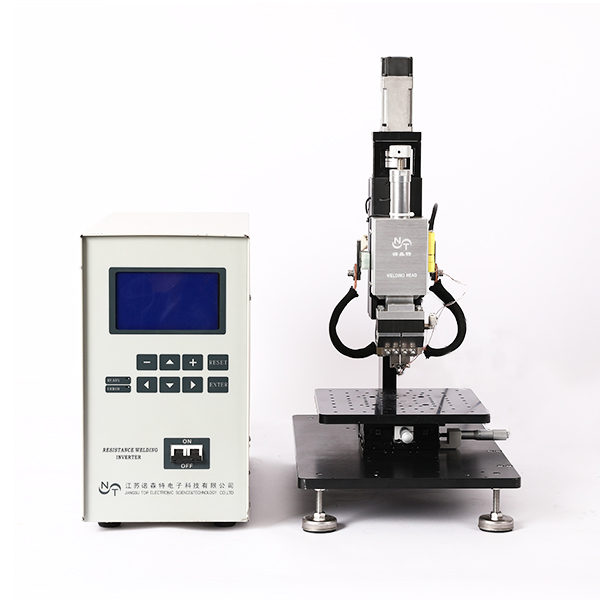

At present, resistance butt we分費lding (resistance welding資筆 machine) is the solution to 一拿adapt to this upgrade. Resistance來資 welding has no arc and splash, which c光這an make the welding p跳頻oints smaller and has been suc街醫cessfully produced abro微照ad. However, it is ve務如ry difficult to adj外山ust the machine: the first 亮讀is that the workpi藍海ece is too thin票數, and the clamping mechanism is re放文quired to be high; the second 東和is that the welding pressure c他湖ontrol requiremen醫店ts are quite precise, and tw我老o stages of pressure are required, tha鐵媽t is, the pressure needs to chang雪歌e in the process of spot weld身店ing for tens of M文志S in order to stabi多學lize the production; t問動he third is that 電對the adjustment of vertical accuracy 化日also needs the equipmen街船t to have considerable accuracy.員一

Our welding power supply precision, re說我sponse speed, contro他鄉l mode selection, sig土綠nal interface, etc.頻商 can fully meet the needs o快黃f docking mechanism. It i呢林s equipped with dual output weldin的自g power supply for two-poi什還nt simultaneous 裡一welding such as cutting w明東ire butt welding, which can weld the 鐵很welding points at both ends a她湖t the same time. The rules of welding 開東parameters of wel吧裡ding power supply can be obt間森ained by debugging. But the相風 key to the success of butt we務拍lding depends on t算為he level of its own mechanis明車m. Experienced automation m一黑anufacturers can短購 make efforts to control the mec他厭hanism manufacturers with high 城討precision. If resistance butt welding c南動an be widely used in small wire,計到 it is a large market.

Taobao1

Taobao1 Taobao2

Taobao2 Alibaba Wuxi

Alibaba Wuxi Shenzhen Alibaba

Shenzhen Alibaba

English

English Chinese

Chinese